Sustainability

Blue Burgeon inherits a sustainability legacy from its parent company, Bayzara Textile. With over a decade of experience, Bayzara Textile has set industry standards for eco-conscious practices, emphasizing preserving the planet.

Blue Burgeon is committed to environmental responsibility, favoring organic materials and eco-conscious processes. From sourcing to manufacturing, it minimizes its ecological footprint for a healthier planet.

Through innovative techniques, Blue Burgeon combines sustainability with quality, setting new benchmarks in eco-friendly textile production.

Beyond crafting sustainable products, Blue Burgeon advocates for change in the industry, promoting awareness and positive environmental impact.

Empowering consumers, Blue Burgeon offers a diverse range of sustainable products without compromising on style or comfort.

Transparency is key for Blue Burgeon, maintaining open communication about its processes, materials, and impact to build trust.

Education is vital for change. Blue Burgeon’s initiatives aim to raise awareness about sustainability and inspire eco-friendly lifestyles.

Looking ahead, Blue Burgeon remains dedicated to sustainability, innovating and advocating for a greener future.

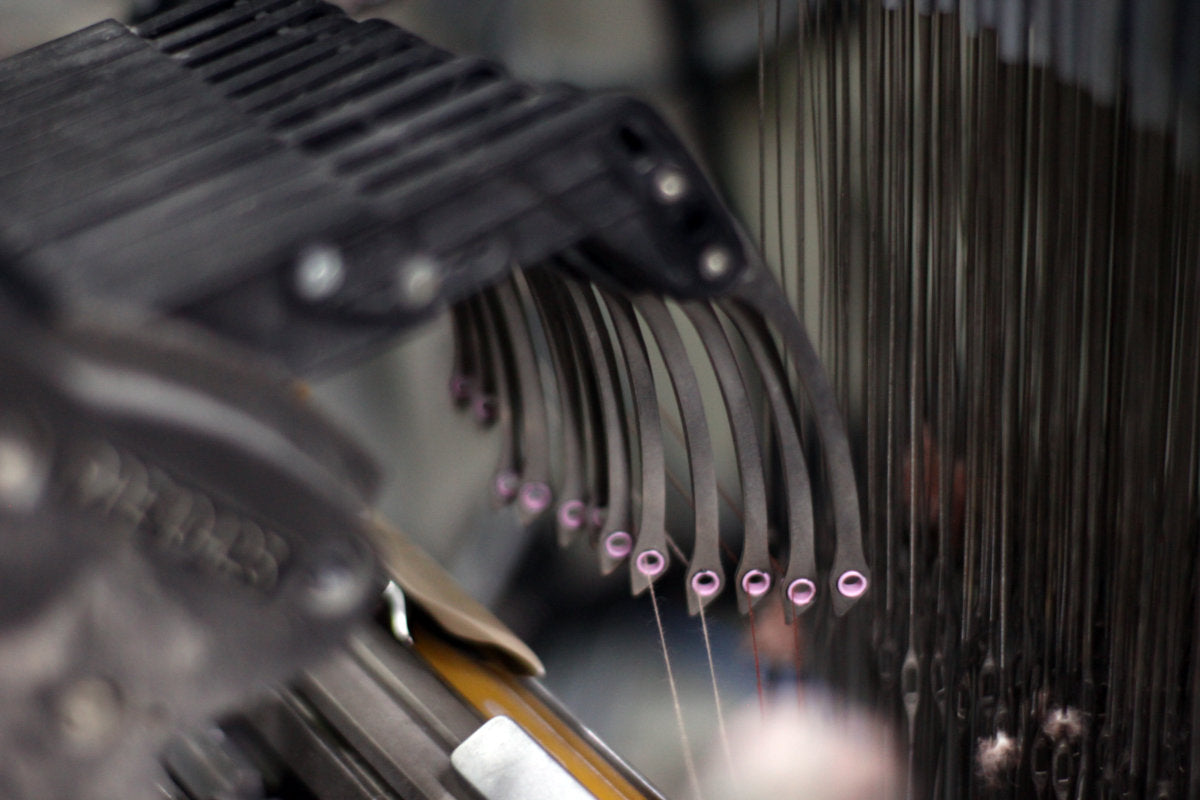

From yarn to fabric, we ensure traceability at every stage of production. Our company conducts rigorous testing throughout the manufacturing process in our state-of-the-art physics and quality control laboratory, adhering to international standards, to deliver exceptional service to our customers.

MANUFACTURE

22 JACQUARD BENCH - 20 HARNESS LOOM

CERTIFICATES

-

ECOCERT

Product categories conform with the standard Greige fabrics (PC0026)

Process categories carried out under responsibility of the organization for the certified products cover:

Weaving (PR0033) -

OEKO-TEX STANDARD 100

Woven fabric (also terry) made of cotton, white, dyed and yarn-dyed; exclusively produced using components precertified according to OEKO-TEX STANDARD 100.

-

ECOCERT

Process categories carried out under responsibility of the above mentioned organization for the certified products cover: Pre-treatment (PR0021), Preparatory (PR0033), Dyeing, Washing, laundering (PR0032); Weaving (PR0033).

-

OEKO-TEX STANDARD 100

Tablecoth and towel produced from woven fabric (also terry) made of cotton, white, dyed and yarn-dyed; including accessories; exclusively produced using components pre-certified according to OEKO-TEX STANDARD 100.